Profile and History

Company Profile

Company name

| Gonda Metal Industry Co., Ltd.

|

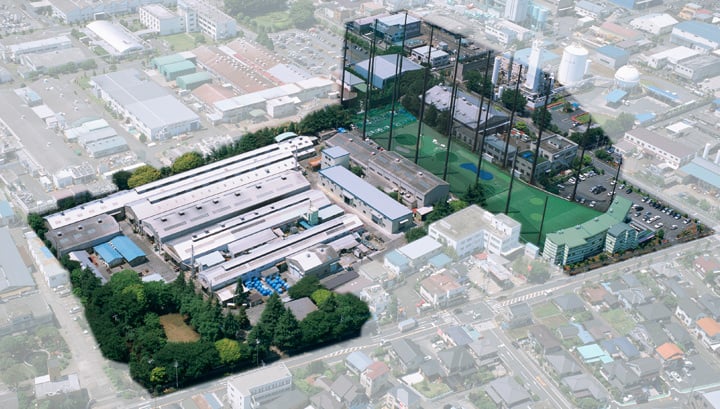

Head Office and Factory

| 1-1-16, Miyashimo, Chuo-ku, Sagamihara, Kanagawa

252-0212 Japan |

TEL /FAX

| +81-42-700-0220 / +81-42-700-0660

|

Representative

| Gonda, Gentaro President

|

Capital

| JPN\60 million

|

Business outline

| Manufacturing and sales of copper busbar, copper/brass round rod, copper anode for plating, die forgings, copper coil materials, high purity non-oxygen copper, special alloy rotor bar, copper/ aluminum/stainless steel rings/plates, magnesium alloy sheet AZ61, Real estate leasing

|

Number of employees

| 90

|

Main customers

| Pan Pacific Copper Co., Ltd., Toyota Tsusho Corporation, Toshiba Corporation, Mitsubishi Electric Corporation, Nikon Corporation, Hakudo Corporation, Sato Metal Trading Co., Ltd. and 200 other users, and wrought copper and copper alloy wholesalers

|

Group business

| Gonda Un・yu Co., Ltd.:Transportation of company products and

management of the golf driving range "Ball Park"

Sagami Metal Co., Ltd.:Wholesaler of raw materials for company use

Yokohama Shindo Co., Ltd.:Sales of wrought copper, copper

alloy products, alminum products and etc.

|

Company History

|

|

| Reorganized into Gonda Shindosho Co., Ltd.

|

1947 January

|

|

1950 September

|

|

| Start of Copper Melting

|

1960 January

| Moved melting and hot rolling plants to the present premises in Sagamihara

|

1963 May

| Moved the headoffice and product plant in Sagamihara, to form a new headoffice and factory.

Headoffice and factory:1-1-16, Miyashimo, Chuo-ku, Sagamihara, Kanagawa, 229-1112 Japan

(Site area:approx.33,000 square meters) (Built a building for rent in the former premises in Nishi-ku, Yokohama. The present tennant is The Daiei, Inc.) |

| Built a forging and pressing plants for the enlargement of the company business

|

1983 November

| Inauguration of the third President, Gonda, Gentaro(present President)

|

1987 March

| Built a new rolling plant for the modernization of the former plant, installed a computer controlled rolling machine

|

1989

|

|

| Obtained JIS indication permission for copper busbar, copper round rod and free-cutting brass round rod

|

| Opened "Ball Park", a golf driving range, in the adjacent space

|

| Obtained ISO 9002 certification, registration Number 0467

|

2001

| Start of mass production for Stainless Rings

|

2002 August

|

|

| Obtained a patent for "METHOD AND APPARATUS PRODUCING THIN MAGNESIUM BASED ALLOY PLATE " JAPAN:P3503898

|

|

|

2008 January

| Obtained NEW JIS certification following a revision of JIS

Certificate number QA0307044 |

2008 June

| Selected as one of “300 of Japan’s Dynamic MONODZUKURI (Manufacturing) Small and Medium Enterprises”

In June, 2008, Gonda Metal was selected as one of "300 of Japan's Dynamic MONODZUKURI(Manufacturing) Small and Medium Enterprises" by the Small and Medium Enterprise Agency of Ministry of Economy, Trade and Industry, and was commended by the minister of METI as a result of the high evaluation on the manufacturing of the precise copper ring(over 60% of the domestic share) used for an industrial motor and the development of mass production for the thin sheet of magnesium alloy AZ61.  |

2011 January

| Purchased the adjacent land of approx. 4950 ㎡ including build-

ings and named as a Second Factory

|

2013 June

|

|

2018 October

| Celebrated its 100th anniversary!

|

2019 May

| Received "Japan Copper Development Association Award"

by contributing to promote the copper demand by

manufacturing and selling Motor End Rings

|