Research and Development

Gonda Metal is not only making efforts to the improvement of the present products but also to the development of a new product for the next generation. We are dealing with the research and development of the next product by the theoretical proof with co-research with universities and laboratories.

Introduction of the research result

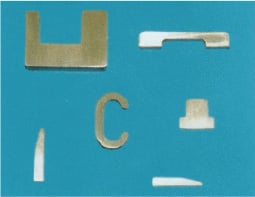

Results of "Development of Copper Deformed Bar by Conform Extruder"

Gonda Metal has succeeded in developing a continuous extrusion molding process for copper deformed bars, thereby making them commercialized. Extrusion by Conform has, in theory, no limitation to extrusion length and can produce shapes that are very close to those of final products. Even deformed shapes as shown in the photo can be extruded in one operation, and fine microstructure and high workability can also be obtained.

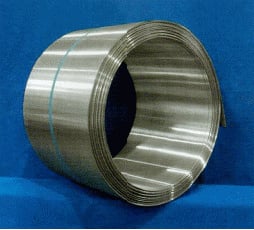

Result of the development of mass-production for magnesium alloy sheet by the hi-speed twin-roll casting system and hot rolling

Magnesium and its alloy are the lightest metal in all metals of practical use and have various useful properties. We have begun to study a new twin-roll casting system which can cast the magnesium alloy sheet directly cooperating with professors of universities since 2002.

As the result, we have successfully developed a new hi-speed twin-roll casting system named "Gonda Twin-roll Casting System" (GTC) and obtained the patent. Various magnesium alloy sheets, which have generally been recognized it is difficult to manufacture magnesium alloy sheets excepting AZ31, can be manufactured by GTRC. GTRC can manufacture various magnesium alloys

such as AZ31, AZ61, AZ91, AM50, AM60 and so on. We are going to study other magnesium alloys except them in the future. In 2008, the mass-production for AZ61 which is excellent in press workability, strength and surface treatment has been started.

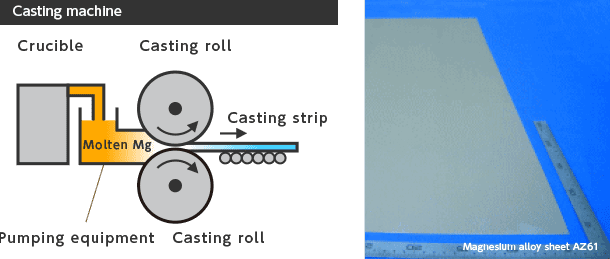

Explation on Gonda Twin-roll Casting(GTRC)

Gonda Metal has developed a new twin-roll casting system(GTRC: Gonda Twin-roll Casting System) to manufacture the magnesium alloy sheet. Not only AZ31 sheet, but magnesium alloy sheets made from AZ61, AZ91, AM50, AM60 and so on can be manufactured of which it has been recognized as difficult to manufacture, by combinig this system GTRC and rolling process.

History of development for Magnesium Alloy Sheet and Press Forming

2002

| Started to develop magnesium alloy sheet as

the next generation material following copper.

Completion of 100mm width sheet.

|  |

2003

| Completion of Gonda Twin-roll Casting System.

By this completion, obtained the patent for “METHOD AND APPARATUS PRODUCING THIN MAGNESIUM BASED ALLOY PLATE”, JAPAN: P3503898.

| |

2004

| Started and completed the development for 300mm width sheet.

| |

2005

| Obtained the international patent for 9 countries. (~2007)

| |

2006

| Started the development for 400mm width sheet.

Introduced the mass production equipment for it.

Aimed at the completion of AZ61 sheet which has

many advances more than other magnesium alloys.

| |

2009

| Determination of supplying subsidy for supporting

product development by MONODZUKURI

(Manufacturing) Small and Medium Enterprises.

By this determination, aimed to complete the press forming technology of magnesium alloy sheet.

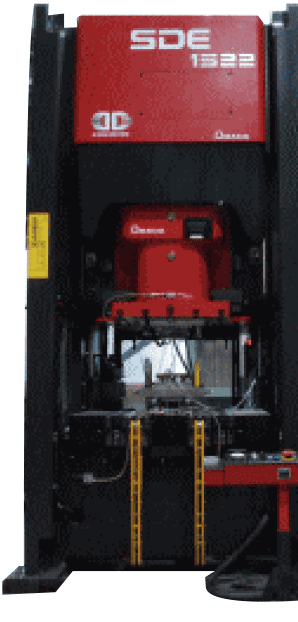

The Digital AC Servo Press made by AMADA CO., LTD., stated in the right picture, has been introduced by the subsidy.

Started the development of 600mm sheet and intro-duced the mass production equipment for it. | |

2010

| Completion of the press forming technology, and the mass production system for 600mm sheet.

| |

2013

| Development for the technology of high-speed twin-

roll casting and rolling, to implement the cost reduc-

tion of the high quality magnesium alloy sheet.

|

Collaborative research with universities and the research institutions

2012~ Friction welding technology with Nihon University

2013~ Surface treatment technology with Yamanashi Industrial Technology Center

2013~ Surface treatment technology with Yamanashi Industrial Technology Center

The patent of this development

"METHOD AND APPARATUS PRODUCING THIN MAGNESIUM BASED ALLOY PLATE"

December 19, 2003:3503898(JAPAN)

May 9, 2007:1614490(EU), USA, Australia, Taiwan, Korea and Russia

December 19, 2003:3503898(JAPAN)

May 9, 2007:1614490(EU), USA, Australia, Taiwan, Korea and Russia

Application of various public subsides

Our research activities have been funded by various public subsidies.

1999 : Kanagawa Prefecture Core Industry Promotion Project Subsidy

2002 : Kanagawa Specific Industry Accumulation and Activation Project Subsidy

2003 : Creative Technology R&D Subsidies of METI

2005 : Kanagawa Prefecture Industial Accumulaton Incentive Program (INVEST KANAGAWA)

2005 : Sagamihara Tomorrow Expansion Project for 50 years (STEP50) (Sagamihara Industrial Accumulation Promotion and Facilities Maintenance Bounty)

2008 : Regional Needs Conformity Project(Japan Science and Technology Agency)

2009 : Regional Needs Conformity Project(Japan Science and Technology Agency)

MONODZUKURI (Manufacturing) Small and Medium Enterprises

(National Federation of Small Business Associations)

2013 : Strategic Core Technology Advancement Program (Supporting Industry Program) (Kanto Bureau of Economy, Trade and Industry)

Sagamihara R&D Subsidies for Small and Medium Enterprises(Sagamihara City)

2002 : Kanagawa Specific Industry Accumulation and Activation Project Subsidy

2003 : Creative Technology R&D Subsidies of METI

2005 : Kanagawa Prefecture Industial Accumulaton Incentive Program (INVEST KANAGAWA)

2005 : Sagamihara Tomorrow Expansion Project for 50 years (STEP50) (Sagamihara Industrial Accumulation Promotion and Facilities Maintenance Bounty)

2008 : Regional Needs Conformity Project(Japan Science and Technology Agency)

2009 : Regional Needs Conformity Project(Japan Science and Technology Agency)

MONODZUKURI (Manufacturing) Small and Medium Enterprises

(National Federation of Small Business Associations)

2013 : Strategic Core Technology Advancement Program (Supporting Industry Program) (Kanto Bureau of Economy, Trade and Industry)

Sagamihara R&D Subsidies for Small and Medium Enterprises(Sagamihara City)