Magnesium Products

Materials

Magnesium Products by Gonda Metal

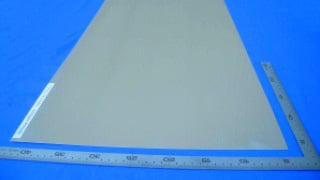

Producible from thin sheet less than 1.0mm through thick sheet over 10.0mm in thick

Producible from thin sheet less than 1.0mm through thick sheet over 10.0mm in thick

Producible Range (mm)

| ||

Thickness

| Maximum Width

| Maximum Length

|

0.8 or over to and incl. 1.0

| 550

| 1800

|

Over 1.0 to and incl. 3.0

| 500

| 1500

|

Over 3.0 to and incl. 10.0

| 400

| 500

|

Over 10.0

| Negotiable, please ask.

| |

For sizes; regarding width or length other than the chart above, please ask the Sales Division.

(e-mail:eigyo@gondametal.co.jp)

We usually provide a sample sheet in A4.

We usually provide a sample sheet in A4.

Standard Specifications of Gonda Magnesium Sheet

Variation of Mg alloy

| Thickness

(mm) | Yield Strength

(MPa) | Tensile Strength

(MPa) | Elongation

(%) |

AZ61

(Al 6%,Zn 1%) | 0.8 or over to

and incl. 10.0

| 160 to 210

| 240 to 300

| 8 to 24

|

Over 10.0 to and incl. 15.0

| 200 max.

| 250 max.

| 5 max.

| |

AZX611

(Al 6%,Zn 1%,Ca 1%) | 0.8 or over to

and incl. 10.0

| 150 to 220

| 240 to 310

| 6 to 20

|

Over 10.0 to and incl. 15.0

| 200 max.

| 250 max.

| 5 max.

| |

AZX612

(Al 6%,Zn 1%,Ca 2%) | 0.8 or over to

and incl. 10.0

| 160 to 250

| 240 to 300

| 5 to 18

|

Over 10.0 to and incl. 15.0

| 200 max.

| 250 max.

| 4 max.

|

All numeric data stated in the above chart are standard. More high strength (high hardness) and/or high ductility (high toughness) is/are possible.

Moreover, to make proto-type by adding minor element, and by controlling crystalline structure and/or microstructure is also possible.

Please inquire any material design for magnesium alloy.

Moreover, to make proto-type by adding minor element, and by controlling crystalline structure and/or microstructure is also possible.

Please inquire any material design for magnesium alloy.

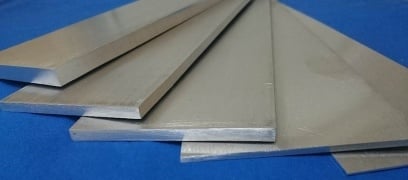

Magnesium Alloy Sheet AZ61

We are now mass-producing AZ61 sheet by combining each process of casting by “GTRC” (Gonda Twin Roll Casting system; originally developed by our own tchnology), subsequently rolling and grinding precesses. AZ61 sheet is superior to AZ31 sheet in strength and corrosion resistance, and can be easily formed by press.

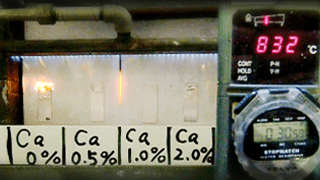

Flame-Resistant Magnesium Alloy Sheet

Recently, we have succeeded in the development of new magnesium alloy sheet which has flame resistance added calcium element by combining each process of casting by “GTRC”, subsequently rolling and grinding prodesses.

Magnesium Alloy for Magnesium Cell

We offer magnesium alloy for magnesium-air fuel cell. Recently the magnesium cell is coming into the spotlight because it is most suitable for emergency power supply use in order that it can be used rightly after having kept it for long term. The shape can prepare not only the sheet but also the round rod.

Building Material from Magnesium

We offer magnesium alloy for building materials. This is a magnesium alloy containing calcium and got the Noncombustible Material Approval from Ministry of Land, Infrastructure, Transport and Tourism (MLIT) in 2013. These sheets are fixed around the suspended ceiling and prevent the collapse of the ceiling when the earthquake and other disasters occur. In the future, applications for wall and others are much expected in the various fields.

Prototype Development on Magnesium Products

Prototype Development on Magnesium Products

Gonda Metal owns various experimental equipment for magnesium products and we can perform melting, casting and rolling. So we can help you to develop new magnesium alloy. On the other hand, we can cope with a trial manufacture for forging and press. Please ask us for a trial manufacture of various magnesium products.

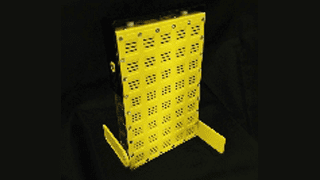

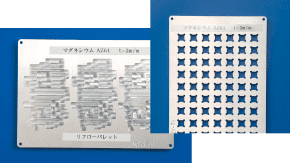

Reflow Palette

Reflow Palette made from Magnesium Alloy AZ61

Magnesium alloy has good heat reaction against the temperature change in the furnace because of its little specifit heat. And Magnesium Alloy AZ61 has both strenght-to-weight ratio and corrosion resistance, moreover, is very good at formability and machinability.

AZ61 is especially the best material for reflow palette.

Die Forgings

Magnesium Alloy Forgings

Gonda Metal is working on the development for die forgings not only the mass production of magnesium alloy sheet. Under the process of our own development and the product condition, it is possible to apply it.

Press Works

Magnesium Alloy Press Works

Housing body which has heat radiation, lightness and strong can be made by pressing because magnesium is excellent in electromagnetic wave shielding property and is satisfactory in vibration absorption and impact absorption. The surface treatment like plating or coating can be also given.

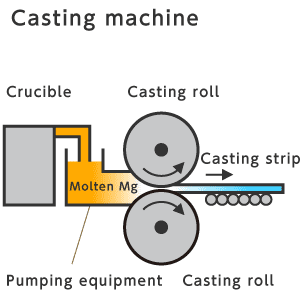

Features of the Manufacturing Method

By rapid cooling system, this system can manufacture as-Cast strip with small grain size and equiaxed crystal. Magnesium alloys of AZ61, AZ91, AM50, AZ60 and etc. besides AZ31, can be manufactured by this system.

This system can obtain high productivity because its high speed casting and the productive balance to rolling process can be easily taken.

Moreover, this as-Cast strip is able to use for a die forging material.

This system can obtain high productivity because its high speed casting and the productive balance to rolling process can be easily taken.

Moreover, this as-Cast strip is able to use for a die forging material.