GTRC

Technology of Gonda

GTRC

Gonda Twin-Roll Casting System

A mass production of magnesium alloy sheet employed with high speed twin-roll casting

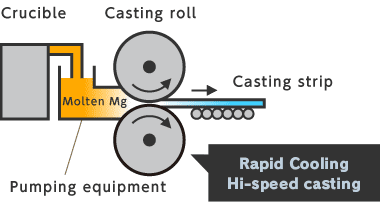

A twin-roll casting technology is a technique to cast directly from molten metal and can largely reduce the number of processes in comparison with conventional manufacturing method. Especially GTRC (Gonda Twin-Roll Casting), developed by our own technology, succeeded in rising the productivity more by increasing its casting speed.

GTRC can produce various alloys such as AZ61, AZ91, AM60 and others as well as AZ31. Gonda Metal has started the mass-production of AZ61 sheet which is superior in the weight-to-strength ratio, the surface treatment, the formability among other alloys since 2008.

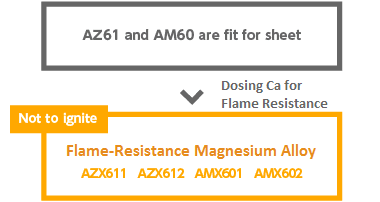

Newly Gonda Metal has started to manufacture an flame-resistant magnesium alloy sheet. The most merit of this sheet is flame resistance; it only melts but does not ignite even if the sheet is heated more than 800 ℃. The use to building materials and others is very expected.

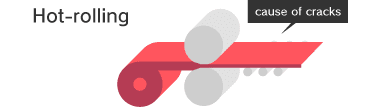

The difficulty of manufacturing magnesium products

Hot-extrusion and hot-rolling are more difficult for magnesium than aluminum and copper. The repetition of hot-rolling causes cracks on the surface of the sheet.

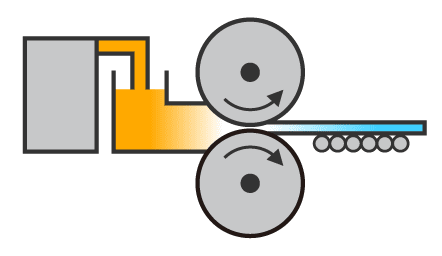

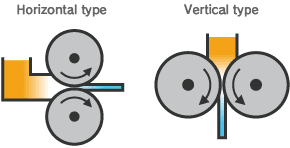

The conventional manufacturing method: What is TRC (Twin-Roll Casting)?

TRC was originally invented for steel in the middle of 19th century. Then TRC was diverted for aluminum in 1930s and finally applied for magnesium alloy in 1980s, and TRC became the main manufacturing method for thin sheet recently.

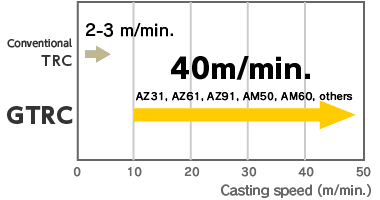

Because the thin sheet can be manufactured directly, it is possible to reduce a hot-rolling process greatly. This will realize reduction of equipment, reduction of processes and energy saving. However, TRC has also disadvantages that the casting speed is very low and variety of magnesium alloy cast by TRC is limited.

Advantages of GTRC

Realized high speed casting without cracks on the sheet

GTRC can realize high speed casting by a rapid cooling system named “Rapid Cooling Hi-speed casting”.

Furthermore, Gonda Metal pushed forward a study and enabled to cast various alloys now. Acquired a patent in Japan in 2003 and major countries in 2007.

Enable to manufacture a rolling sheet in 1.00 mm thickness

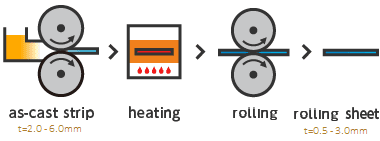

As for the conventional manufacturing method for a thin sheet, it is necessary to repeat heating and hot-rolling around 30 times, after produce a block of 80 mm in melting and casting processes. But it needs only few times of rolling process for manufacturing the sheet in 1.0 mm thickness because the twin-roll casting can produce as-cast strip in 2.0~4.0 mm thickness directly.

More than 10 times of the casting speed than conventional TRC

By improving the cooling method, it is possible to implement more than 10 times of the casting speed than the conventional TRC. GTRC can cast various kinds of magnesium alloy.

GTRC can produce calcium contained magnesium alloy sheet easily

GTRC can produce magnesium alloy sheet having flame resistance. In case of AZX611 and AZX612, each approx. 1% and 2% of calcium is contained and incase of AMX601 and AMX602, each approx. 1% and 2% of calcium is also contained.