Reflow palette made from Magnesium Alloy AZ61

Reflow palette made from Magnesium Alloy AZ61

In recent years, a reflow soldering is becoming a main method along with miniaturizing and high precision accuracy of parts in mounting electronic parts on the PCBs (Printed Circuit Boards). For obtaining the protection of electronic parts and the productivity improvement, the importance of the reflow palette used in the reflow furnace is increasing and the reflow palette made from Magnesium Alloy AZ61 has the most suitable features stated as follows;

Excellent merits in the reflow palette made from AZ61

For improving the workability

The productivity improvement can be obtained by improving the workability because magnesium is the lightest in all the commonly used metals (specific gravity of AZ61: 1.8).

Easy control on the temperature

Because magnesium alloy has a little specific heat and good heat reaction against the temperature change in the furnace, it is possible to obtain the correct temperature adjustment.

Good in durability

The palette made from AZ61 has longer life than the palettes made from other metals or resins because the strain against the temperature of magnesium alloy is very little and has an excellent dimensional stability.

Achievement of total reduction in costs

The total reduction in costs can be achieved by above items 1 ~ 3.

Very good balance at Magnesium Alloy AZ61

Though many other magnesium alloys also fit for the reflow palette, AZ61 is especially the best material. Because AZ61 has both weight-to-strength ratio and corrosion resistance, more over is very good at formability and machinability. The sheet of 1.0~3.0 mm in thickness is generally used.

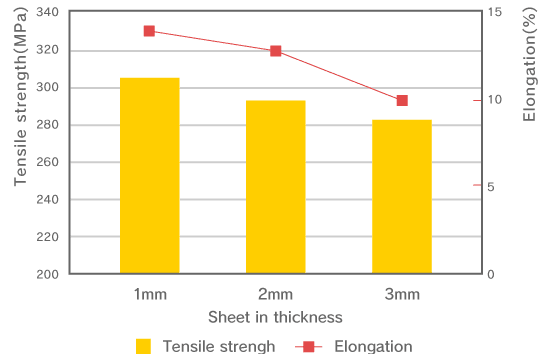

Mechanical Property

Tensile strength and elongation at room temperature AZ61

A popular size of sheet for reflow palette

Thickness : 1~3mm

Width : ≦ 600mm

Length : 1,000mm

Width : ≦ 600mm

Length : 1,000mm

※Please make an inquiry if you have any requirements in thickness, width and length for the sheet.

Chemical composition of AZ61(%)

Al

|

| Sl

|

|

|

| Fe

|

|

Mn

|

| Ni

|

|

Cu

|

| Mg

| Bal.

|