Flame-Resistant Magnesium Alloy Sheets

Flame-Resistant Magnesium Alloy Sheets AZX/AMX

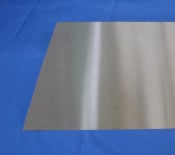

Gonda Metal has produced the magnesium alloy sheet AZ61 which is superior to AZ31 sheet in the strength-to-weight ratio, corrosion resistance by combining each process of casting by GTRC (Gonda Twin-Roll Casting system; originally developed by our own technology), subsequently rolling and grinding processes. Recently, we have succeeded in the development of new magnesium alloy sheet which has flame resistance by adding calcium element.

Production range of AZX/AMX sheet (dimension of sheet)

Thickness

| Width

| |

Casting strip

| 2.0~4.0mm

| ≦630mm

|

Rolling/Grinding sheet

| 0.5~3.0mm

| ≦600mm

|

Chemical Composition (%)

AZX

| |||

Al

| 5.8 - 7.2

| Zn

| 0.4 - 1.5

|

Mn

| 0.15 - 0.5

| Cu

| ≦ 0.05

|

Si

| ≦ 0.1

| Fe

| ≦ 0.005

|

Ni

| ≦ 0.005

| Mg

| Bal

|

Ca

| AZX611=1.0%

AZX612=2.0% | ||

AMX

| |||

Al

| 5.6

| Zn

| ≦ 0.2

|

Mn

| 0.26

| Cu

| ≦ 0.008

|

Si

| ≦ 0.08

| Ni

| ≦ 0.001

|

Be

| ≦ 0.0005

| Mg

| Bal

|

Ca

| AMX601=1.0%

AMX602=2.0% | ||

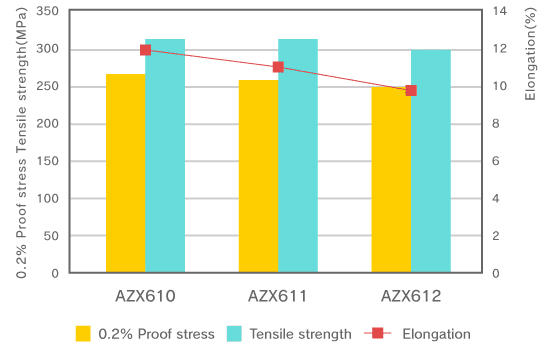

Mechanical properties of AZX

Rolling sheet of 1.0 mm in thickness is used

Combustion test of AZX Alloy

The AZ61 sheet contained Ca only melts in a 1200℃ flame, but does not ignite.

Video①

The flame resistance comparison test at 800℃

In the test at 800℃, the specimen AZ61 without Ca burns, but the specimens AZX610 (Ca 0.5%), AZX611 (Ca 1.0%) and AZX612 (2.0%) do not catch a fire.

The flame resistance comparison test at 800℃

In the test at 800℃, the specimen AZ61 without Ca burns, but the specimens AZX610 (Ca 0.5%), AZX611 (Ca 1.0%) and AZX612 (2.0%) do not catch a fire.

Video②

The flame resistance test AZX612 at 1200℃

The specimen AZX612 (Ca 2.0%) only melts in 1200℃ flame but does not burn.

The flame resistance test AZX612 at 1200℃

The specimen AZX612 (Ca 2.0%) only melts in 1200℃ flame but does not burn.

Workpiece by AZX and AMX

It is confirmed that it is possible to perform warm press forming for AZX and AMX, originally developed by Gonda Metal, as much as AZ61 and AZ31.

Therefore it is possible to perform welding as one of the joining method.

Moreover it is also possible to perform plating on them as a surface treatment.

We can supply rolling/grinding finished sheets made of AZX611, AZX612, AMX601 and AMX602 with 0.5 mm to 3.0 mm in thickness and up to 600 mm in width.

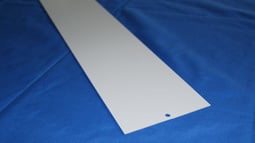

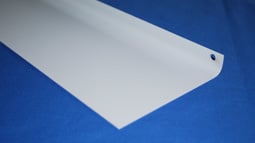

Photos showing in below are workpiece produced by us for example of flame-resistant magnesium alloy sheet. We believe that they can be suitable for components which need flame resistance such as vehicle and so on.

Therefore it is possible to perform welding as one of the joining method.

Moreover it is also possible to perform plating on them as a surface treatment.

We can supply rolling/grinding finished sheets made of AZX611, AZX612, AMX601 and AMX602 with 0.5 mm to 3.0 mm in thickness and up to 600 mm in width.

Photos showing in below are workpiece produced by us for example of flame-resistant magnesium alloy sheet. We believe that they can be suitable for components which need flame resistance such as vehicle and so on.

Cold bending of AZX

t=1.0 mm sheet is used, inner R =10.0 mm.

Spray coating in white after chemical conversion treatment

t=1.0 mm sheet is used.

Spray coating in white after chemical conversion treatment

Cold bending, inner R = 5.0 mm

We believe these flame-resistant magnesium alloys are useful for weight reduction of railway vehicle and automobiles, and are suitable for buildings as a light-weight material.

In November 2013, the building material using our flame-resistant magnesium alloy sheet obtained the Noncombustible Material Approval from Ministry of Land, Infrastructure, Transport and Tourism (MLIT).

In November 2013, the building material using our flame-resistant magnesium alloy sheet obtained the Noncombustible Material Approval from Ministry of Land, Infrastructure, Transport and Tourism (MLIT).